In the industrial hub of Toluca, Mexico, water scarcity is a critical operational challenge. To solve this, the CCRO UAT Team solution was implemented for a major global beverage company needing to optimize its primary water treatment. The facility relies on well water («Pozo»), and traditional Reverse Osmosis (RO) systems were limited by a «recovery ceiling,» typically capping efficiency at 75%.

What is the Difference Between CCRO and Standard RO?

To understand the results in Toluca, it is essential to define the technology.

-

Standard Reverse Osmosis (RO): Typically operates with a fixed recovery rate, often capped at 75% to prevent membrane scaling.

-

Closed Circuit Reverse Osmosis (CCRO): A dynamic process that recirculates feedwater until a specific concentration is reached. This allows systems to safely achieve up to 98% recovery, drastically reducing waste.

Case Study: Breaking the 75% Recovery Barrier

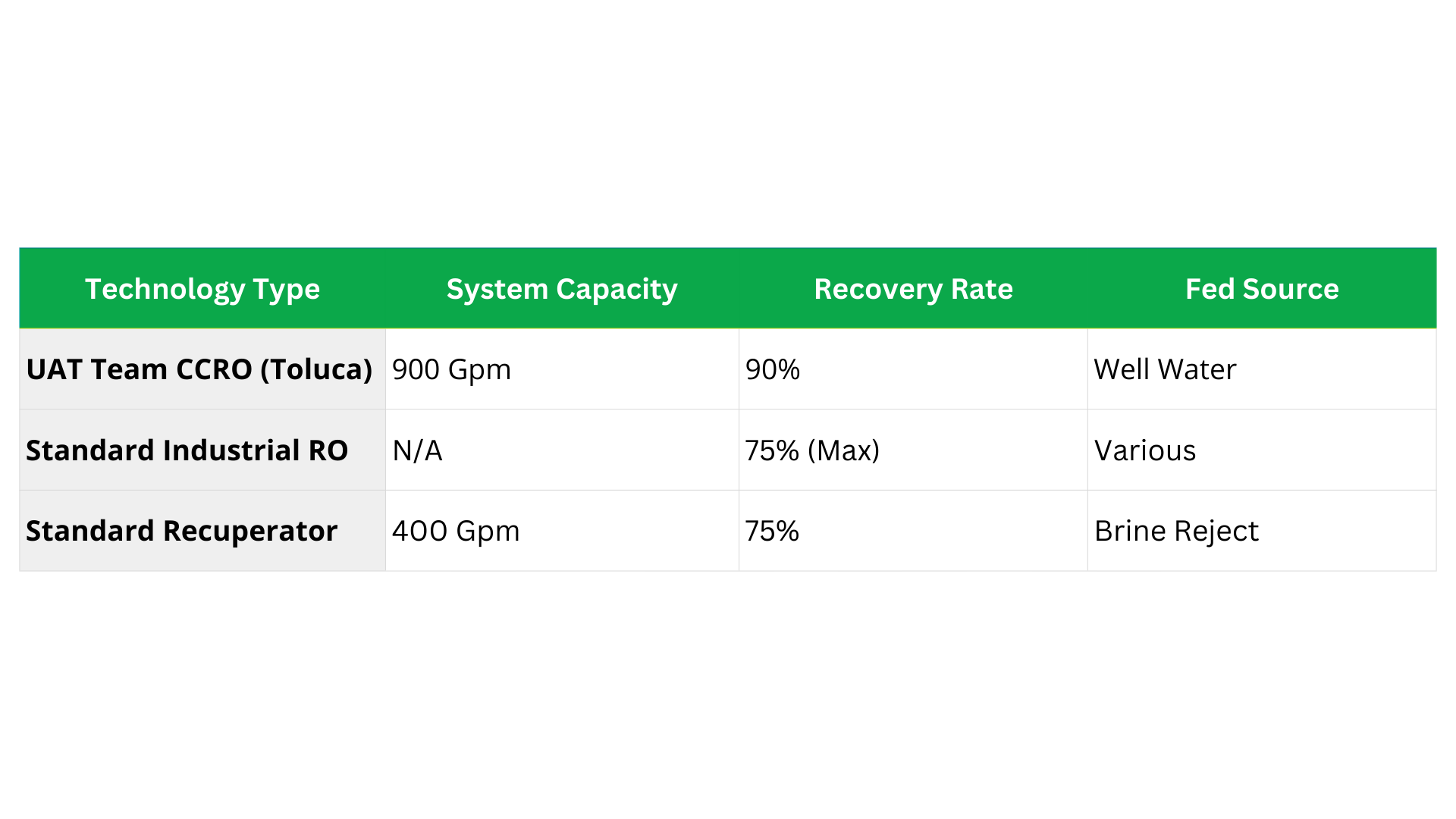

We analyzed the performance data from our latest installation in a major beverage facility in Toluca. The goal was to compare the efficiency of UAT Team’s CCRO technology against conventional market standards.

Performance Data: 900 Gpm Primary CCRO

The facility utilizes a primary CCRO system fed by well water (Pozo). The results highlight a massive efficiency gap compared to traditional systems.

Why High Recovery Matters: The Strategic Benefits of CCRO

Why should a plant manager upgrade from standard Reverse Osmosis to CCRO? The shift from 75% to 90% water recovery offers four strategic advantages for industrial manufacturing:

1. Reduced Operating Costs (OPEX)

By recovering 90% of the feedwater, facilities significantly lower their raw water procurement costs. In high-volume industries like beverage bottling, CCRO technology directly improves the Cost of Goods Sold (COGS).

2. Competitive Pricing Advantage

Efficiency drives competitiveness. Plants utilizing high-recovery RO systems can minimize production expenses, allowing for more flexible pricing strategies in the global market.

3. ESG and Water Stewardship

Sustainability is no longer optional. Closed Circuit Reverse Osmosis minimizes brine discharge volume. This helps global brands meet their Environmental, Social, and Governance (ESG) goals by reducing their water footprint in water-stressed regions like Mexico.

4. Scalability Without New Permits

In regions where water rights are capped, the only way to increase production is to waste less water. A 90% recovery rate allows plants to expand capacity using their existing water allocation—a feat impossible with standard 75% efficient RO systems.

Conclusion: Upgrade Your Industrial Water Treatment

The data from Toluca is clear: Standard Reverse Osmosis is no longer the ceiling.

If your facility is still operating at 75% recovery, you are missing a critical opportunity for optimization. UAT Team specializes in engineering and manufacturing CCRO systems in Miami for export globally.

Ready to optimize your Water Use Ratio (WUR)? Contact UAT Team today for a technical audit. Discover the potential of switching to Closed Circuit Reverse Osmosis.